The company presents a more sustainable alternative to the market after months of research and validation, confirming that it provides moisture protection equivalent to a 120-gram PVDC coating.

NutraResearch introduces to the pharmaceutical and dietary supplements market an innovative sustainable blister packaging, which can replace the current options combining plastic and aluminum that make them non-recyclable.

In line with its values and in accordance with the European Union’s circular economy strategy for plastics, the company has conducted extensive research and analysis, allowing it to take the lead in the industry by offering a new sustainable packaging solution to its customers.

Currently, various materials are used for blister packaging, the primary packaging widely used in the pharmaceutical sector for tablets and capsules. Among them, PVC/PVDC and aluminum stand out as oxygen barriers to protect the product from moisture, preventing degradation over time. However, the combination of plastic and aluminum used to seal the blister makes it impossible to separate these materials, rendering them non-recyclable. Additionally, non-recyclable inks are often used in pre-printed aluminum.

NutraResearch’s sustainable blister is an innovative proposal in thermoformed blister systems that provides moisture protection equivalent to a 120-gram PVDC coating.

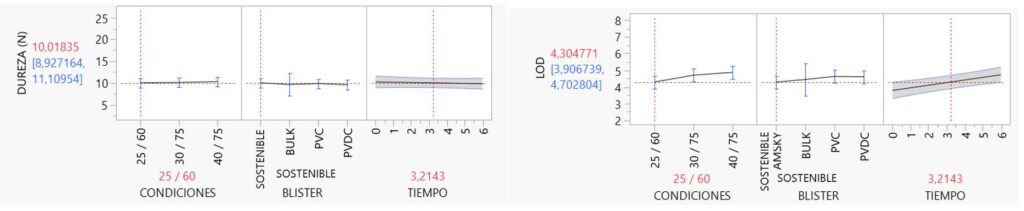

Validation studies have confirmed this. NutraResearch has conducted stability studies using this new sustainable alternative, meeting the requirements of ICH Q1A: it has selected the best-selling products, those with different preservation characteristics, as well as those most sensitive to potential changes or considered “worst-case” scenarios (due to their hygroscopic nature, containing plant extracts, or sensitive actives). They have subjected these products to various temperature and humidity conditions, reaching accelerated and extreme stress scenarios of 40°C and 75% relative humidity for six months. After this period, their condition was analyzed, comparing it with PVC and PVDC blisters typically used.

“The stability study results conducted in Nutraresearch’s pilot plant have demonstrated that this material provides a moisture barrier protection comparable to PVC and PVDC blister packaging,” explains the study’s lead, Javier Sala.

This marks the first time that a 100% recyclable blister has been introduced to the market. “After analyzing market trends and their evolution, we have proactively invested in the development of this sustainable packaging. We believe there is future demand, and this way, we are ahead to meet the new needs of our customers,” says Gemma Casadevall, General Manager of NutraResearch. This move demonstrates NutraResearch’s commitment to continuous innovation in the pharmaceutical sector by offering new, high-quality, and reliable nutraceutical solutions.