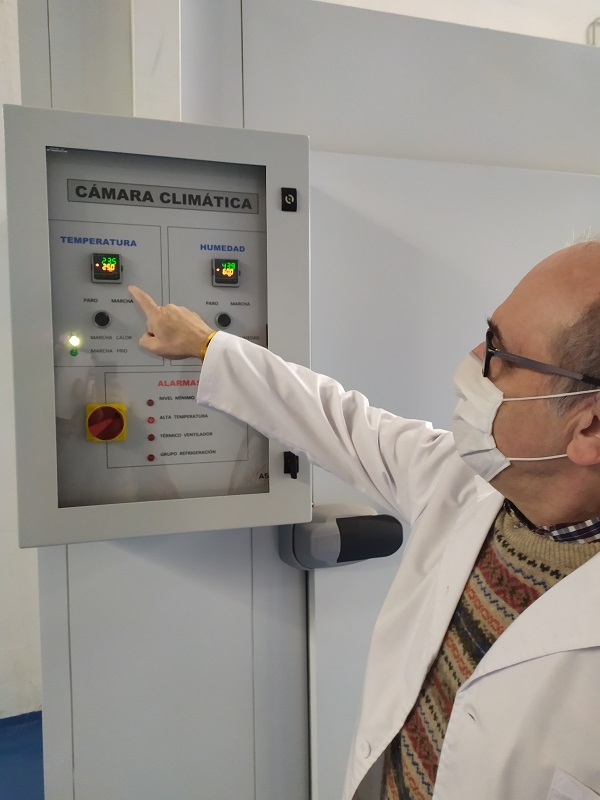

Despite not being mandatory, NutraResearch carries out, thanks to its advanced technology, stability tests during the development of food supplements. Once they are on the market, on going test are kept to continue guaranteeing the high quality of the product.

Food supplements can come a wide variety of pharmaceutical dosage forms and packaging, but this translates into different stability case studies for each of them. Food supplements are intended to deliver actives with a nutritional or physiological effect, so it should be ensured that their specifications, considered critical, whether physical, chemical, or organoleptic characteristics, remain unchanged throughout the product’s shelf life, that is, until the expiration date printed on the label.

It is important to emphasize that the stability of all products is essential not only to guarantee their quality but also to satisfy the needs and expectations of our consumers. Factors that can influence product stability are many and may include:

-Environmental conditions (temperature, humidity, UV light, etc.).

-Possible interactions amongst components.

-Physical characteristics of the product (liquid, solid, etc.).

-Characteristics of the packaging material (permeability to oxygen and water vapor, etc.).

It is essential that these variables are carefully evaluated during product development stages so that we achieve a robust formulation on the market.

NutraResearch group has advanced technology applied in all phases of the formulation. This is how we study possible interactions and incompatibilities between the excipients of the proposed formulation, carried out in-house using DSC (Differential Scan Calorimetry) technology. With this, it is possible to detect potential changes into the physical state of the composition, detect incompatibilities and also foresee stability problems faster.

In addition, once the product is marketed, it is highly recommended to continue monitoring its stability. This is how, through the “on-going” stability studies, a continuous control is maintained thanks to which it is possible to detect any potential stability issues associated with the formulation in the final packaging marketed during the entire shelf life of the product.

There are several types of stability studies and the manufacturer of the food supplement should select one that is most appropriate for the required information. Studies can be classified into the following categories:

– Stress tests, to determine the susceptibility to degradation of an ingredient or combination of ingredients.

– Accelerated/stress testing, where storage conditions are meant to accelerate the rate of any change and therefore reduce study time.

– Long-term tests, in which the storage time is equal to or greater than the expected shelf life. This is also known as ‘real time’ study.

– Transit test, which is used to simulate shipping and storage conditions during product distribution.

– in use Studies, which are used to simulate the stability of a multiple-dose product after opening it and during use by the consumer.

Regulatory requirements in most countries of the European Union does not entail stability tests in the case of food supplements. However, they have begun to publish guidelines as common good practices given the critical consequences that not conducting stability studies can have on the market.

Ideally, the development of food supplements should be based, like for pharma products, under ICH Q8 (quality by design) guideline, where the proposed formulation should be critically studied. Likewise, to evaluate the impact on its stability, ICH Q1A guideline should be taken into account, to identify three key aspects such as incompatibilities; interactions or instability caused by temperature, humidity or light; and problems during shipping or storage. Despite not being mandatory, NutraResearch carries out all these processes, since it applies maximum rigor of the pharmaceutical sector to the development of food supplements.

Not considering all the above during product development can potentially lead to a product recall or a significant reduction in its shelf life. NutraResearch always works to ensure the highest quality of its food supplements, to guarantee the good health of consumers.